4.3 Drain, Waste, and Vent (DWV)

Drain, Waste and Vent (DWV) systems can be complex and extensive as pipe routes are a result of determining fixture locations, fixture requirements, relative codes, construction obstacles, and company installation standards. Understanding of the basic layout of these systems can be crutial to plumbers and maintenance technicians when diagnosing and clearing blockages, and troubleshooting other drain and sewer abnormalities.

DWV Terminology

Building Sewer

A building sewer is the main pipe used to transport sewage and wastewater from a DWV system to a point of disposal, or termination (ex. a municipal sewer line).

Clean-Outs

The start of a building sewer is typically where a clean-out is installed with its connection to the building drain. Clean-outs are installed in various locations throughout a system and the maximum distances are found in a code books, they typically cannot be more than 100’ apart. All codes dictate that the base of every stack and the transition from a building drain and building sewer must have a clean-out installed. Sizing is based on a clean-out being the same size as the pipe when serving a stack, building drain, and building sewer, but some codes allow exceptions for pipe sizes larger than 4”.

Clean-Out Key by Gwen Arkin is licensed under CC BY 4.0

Building Drain

The building drain is the lowest horizontal portion of a drainage system and receives discharge from waste stacks and horizontal branches. Many codes state that it must extend at least 2’-6”and a maximum of 10’-0” from the exterior of the building.

Waste Stack

The waste stack is the main vertical pipe that starts with its connection at the building drain and terminates with its connection to the stack vent. It receives discharge from all horizontal branches and must have a clean-out at its base.

Stack Vent

The vent for the waste stack is known as the stack vent and begins at the highest branch connection to the waste stack. It is a dry piping system that typically extends through the roof, but can connect with the vent stack prior to terminating to open air.

Vent Stack

A vent stack is sized based on numerous factors including the total discharge load of a system and the length it travels. The vent stack can transition horizontally without requiring a relief vent. Like all horizontal vents, it must have adequate slope to eliminate moisture from settling and obstructing its airway. A clean-out is most often required to be installed at its base by plumbing and building codes .

Fixture Drain

The fixture drain serves a single fixture trap and is sized based on the particular fixture load. Most codes allow a removable joint of a trap assembly to act as a clean-out for a fixture drain. A floor drain or shower drain with a removable strainer can also serve as a clean-out for a fixture drain. Though a drain cannot be smaller than 1 -1/4” diameter, most codes dictate that the smallest drain size buried below ground is 2” diameter.

Fixture Branch

The fixture branch is a drainpipe that connects more than one fixture drain to a horizontal branch or major segment of a DWV system.

Horizontal Branch

A horizontal branch is a drainpipe that connects horizontally to a major segment of a DWV system. It can either connect to a waste stack or building drain. It connects more than one fixture drain or a fixture branch to a main segment of DWV system.

Individual Vent

Individual vents serve one fixture trap and are a vertical extension of a drain. They must be at least half the diameter of the drain they serve, but no smaller than 1 -1/4”.

Branch Vent

The branch vent serves as a vent for a horizontal branch and connects to the a vent stack or a stack vent. A branch vent is sized based on the size of the horizontal branch, the drainage load of the horizontal branch, and the distance it travels.

Circuit Vent

A circuit vent, mainly used in commercial applications, is a branch vent that is not typical with other standard branch vent types and has specific code regulations. Single-family residential construction typically does not use “battery” configurations designed for institutional style multiple fixture applications due to the minimal number of fixtures located within one room.

Loop Vent

The loop vent is a circuit vent that is installed on a top floor of a building or highest branch. All sizing and code regulations are the same as those for a circuit vent.

Relief Vent

A relief vent is required when a waste stack transitions from vertical to horizontal. The most common relief vent is one serving a battery of fixtures. A relief vent serving a battery of fixtures is sized based on being half the diameter of the horizontal branch, but as with all other vents, it cannot be less than 1 -1/4”.

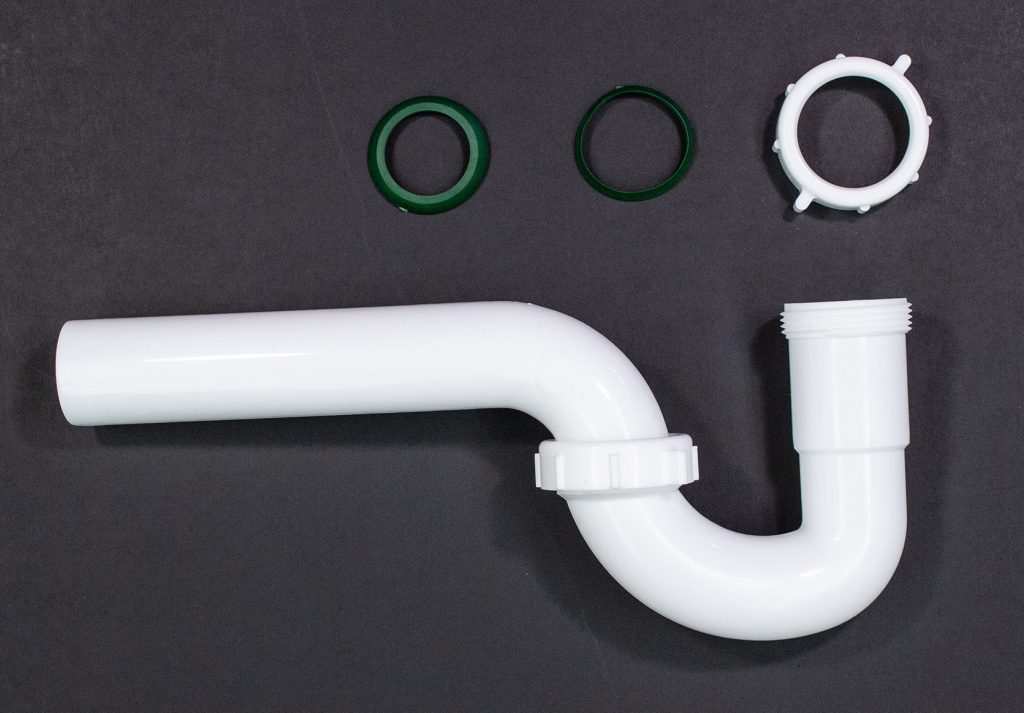

Trap

Every plumbing fixture connected to a drainage system must be protected by a fitting or device that serves as a protective water seal to prevent harmful sewer gas from entering an occupied space. This device is called a trap. A p-trap gets its name from its appearance, which resembles the letter P, and is installed receiving the outlet flow of waste water from a fixture. P-traps are available in a variety of styles, which include one-piece and two-piece designs and are designed to serve wall entry connections to the branch drain pipe, whereas S-traps are designed to serve floor entry connections to the drain pipe. The joints of a trap and it’s connections to the drain and fixture it serves are commonly assembled with compression style fittings similar to a union.

P-Trap by Gwen Arkin is licensed under CC BY 4.0

Trap Adapter

A slip-joint p-trap is tubular size and has a smaller outside diameter than the connecting DWV pipe. The fitting for connecting tubular sizes to DWV pipe sizes is referred to as a trap adapter and sometimes also called a desanco. A trap adapter is usually installed during the fixture installation phase of a project. Cast iron, copper, and galvanized piping systems use brass trap adapters.

Drain Cleaning

If you talk to any plumber or maintenance technician that has long-term experience with clearing clogged sewer and drain lines, you’ll be amazed with the stories of the unthinkable items they have cleared or retrieved from DWV systems. Food and human waste, jewelry, silverware; toys, mop heads, and tree roots; beach towels, linen, and personal hygiene products; birds’ nests, tree waste and fruit dropped by animals into vent systems, and more, They’ve seen it all!

Chemical drain cleaners, plungers, hooked flexible plastic extraction devices, and other gadgets can clear clogged p-traps and other clogs in drain lines relatively close to fixtures, some clogs require plumbing and maintenance technicians to use a manual or motorized drum auger to clear them.

How To Unclog a Drain Using a BrassCraft Drum Auger

If a hand or drill operated auger does not clear a clog, a heavy-duty motorized auger may need to be run through a clean-out to clear the obstruction. An assortment of auger heads can be attached to the auger cable to cut through obstructions like human and food waste, tree roots, and other malleable objects, or grab and retrieve objects dropped or flushed down drains.

Easy Rooter Power Drain Cleaner – How To Video

Drain service technicians are sometimes unable to clear obstructions an use a drain and sewer inspection camera to identify what the obstruction is, and with a locator accessory, can pinpoint the location and depth of the obstruction in relation to the piping route including depth.